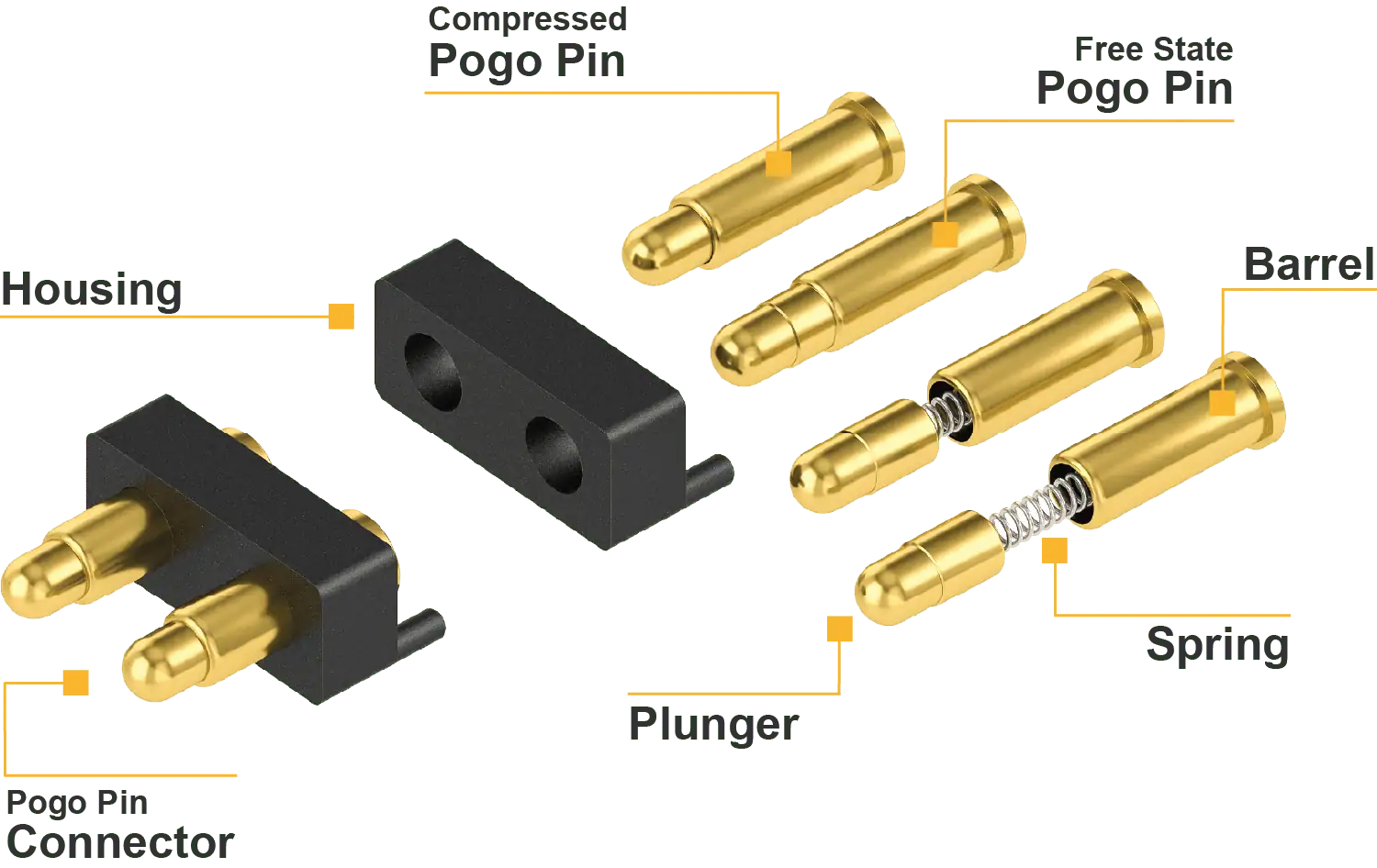

Pogo-Pins

Compact, durable, and reliable

Our pogo pins (spring-loaded contacts) provide reliable, repeatable connection solutions for demanding electronic applications in test systems, connectors, and industrial environments.

With a wide variety of available designs – from standard spring contacts to waterproof and magnetic pogo connectors – we offer the right solution for every challenge.

Your benefits:

- Reliable and stable current transmission – thanks to precise spring mechanics and multiple contact points

- Extremely long service life – over 1,000,000 cycles with minimal wear

- Compact form factor – ideal for space-saving, high-density electronic designs

- Flexible integration – suitable for both SMD and THT assembly; also available as modular connection systems

- Customizable configurations – including length, spring force, head shape, and contact materials

Pogo pins – Precision spring contacts for reliable connections

Our pogo pins (spring-loaded contacts) stand for high contact reliability, long service life, and versatile application potential. They are used wherever compact, solderless, and repeatable electrical connections are required – such as in test systems, charging contacts, wearables, automotive electronics, and industrial applications.

With years of development experience and advanced manufacturing technologies, we offer a wide range of high-quality contact pins that can be tailored to meet specific customer requirements.

Standard pogo pins

Durable spring-loaded contacts with various head shapes, spring forces, and lengths – ideal for test adapters, test systems, and modular connector solutions.

Waterproof pogo pins (IP67/IP68)

Specially designed pogo pins with integrated seals for use in humid or dusty environments – ideal for outdoor devices, wearables, and charging contacts.

Magnetic pogo pin connectors

Innovative, magnetically guided connection solutions for fast and intuitive mating and release – ideal for consumer electronics, medical devices, and docking applications.

High-current pogo pins

Spring-loaded contacts for current transmission in the multi-ampere range – featuring specialized contact materials and optimized spring mechanics for maximum conductivity.

High-frequency pogo pins (RF)

Specially shielded RF pins for high-frequency transmission up into the GHz range – ideal for communication modules, antenna testing, and EMC-sensitive applications.

SMD & SMT pogo pins

Surface-mountable pogo pins for automated assembly – space-saving, solderable, and ideal for compact device assemblies.

Custom pogo pin solutions

Tailored configurations in length, housing, spring force, material coating, or contact geometry – according to your specific requirements for size, current rating, or service life.

Our strengths

- Technology leader in pogo pin solutions: We offer extensive expertise in pogo pin design and modular connector systems, including fully automated manufacturing processes.

- Long-lasting quality & High durability: Our pogo pins provide lifespans of up to 1 million cycles, maintaining consistently low contact resistance throughout their use.

- Flexible designs for any application: From ultra-compact formats< <1 mm to high-performance power and signal connectors – we deliver precisely fitting spring contacts for every installation scenario.

- High vertical integration & Quality assurance: All products undergo 100% electrical and mechanical testing and are designed for long-term stability and resistance to environmental influences.

Applications

Applications

Test systems & Test fixtures: for ICT, FCT, wafer-level testing, and PCB contact – precise, repeatable connections without soldering.

Portable & Mobile devices: Connection solutions for wearables, smartwatches, headsets, or mobile scanners – often featuring magnetic alignment and IP protection.

Automotive & E-Mobility: Charging contacts, onboard electronics, ECU testing – robust and vibration-resistant designs.

Medical technology: Reliable contact solutions for diagnostic systems, patient interfaces, and medical docking applications – hygienic, durable, and low-maintenance.

Industrial & Automation: Connections for moving parts, modular systems, or rugged sensor/actuator interfaces – dependable under load and in harsh environments.

Conclusion:

Our pogo pins offer maximum reliability, flexibility, and durability. Whether for ultra-compact devices or high-current applications – we deliver the perfect solution for your connection needs.

Send us your non-binding

product inquiry.

FAQs

What advantages do pogo pins offer over conventional connectors?

Pogo pins require no mating connectors, are space-saving, durable, and easy to integrate. They enable up to 1 million contact cycles with consistently reliable conductivity – making them ideal for testing, docking, or modular systems.

Are there different pogo pin form factors available?

Yes. Spring-loaded contacts are available in various lengths, diameters, spring forces, head geometries, and connection types.

How is contact resistance ensured?

A multi-point contact surface combined with uniform spring pressure keeps the resistance low and stable – even over many mating cycles and under vibration.

Are custom pogo pin solutions available?

Yes, we offer tailor-made spring contact solutions in terms of length, geometry, spring force, surface coating, mounting type, and environmental protection.

Are pogo pins suitable for vibration or mobile applications?

Yes. Many variants are mechanically secured or magnetically guided to ensure reliable contact even under movement, shock, or vibration.

Are pogo pins suitable for automated assembly?

Yes. SMD and SMT pogo pins are pick-and-place compatible and can be machine-mounted onto PCBs – ideal for high-volume production.

Five good reasons to choose pogo pins from etronics

Engineering Support

We support you throughout development and the entire product lifecycle with our engineering expertise and years of experience.

Short development and Production times

Thanks to our large production capacities, we meet even demanding lead times and delivery schedules.

Quality is our top priority

We strictly follow established quality standards and apply rigorous selection and testing processes for our partners – including validation upon request.

Fast delivery from our Swiss warehouse

Our warehouse ensures your flexibility. For many customers, we hold stock and can deliver replenishments to their facility within two days.

Small series? No problem.

We also manufacture small and very small series of customized spring contact solutions – tailored to your specific needs.

A smooth process from start to finish: Professional project execution

1. Your inquiry

2. Feasibility check & Solution development

3. Customized quotation

4. Project kickoff & Order placement

5. Prototyping & Sample production

6. Sample approval & Optimization

7. Series production & Quality assurance

8. Delivery & Logistics solutions

Explore more categories

Membrane keypads

Durable, hygienic, and fully customizable – highly resistant, easy to clean, and designed to meet your specific needs.

Resistors by MIBA

MIBA high-performance and precision resistors: non-inductive, compact, and reliable.

Displays

Premium TFT, OLED, and LCD displays – fully customizable, offering excellent contrast and energy efficiency.

Touch Panels

Capacitive and resistive touch panels – robust, highly accurate, multitouch-enabled, and easily integrated into your device design.

Silicone Keypads

Durable and tactile input solutions – fully customizable silicone keypads with excellent chemical resistance.

Custom Cable Assemblies

Individually manufactured to exact specifications and industry standards – safe, precise, and perfectly fitting.

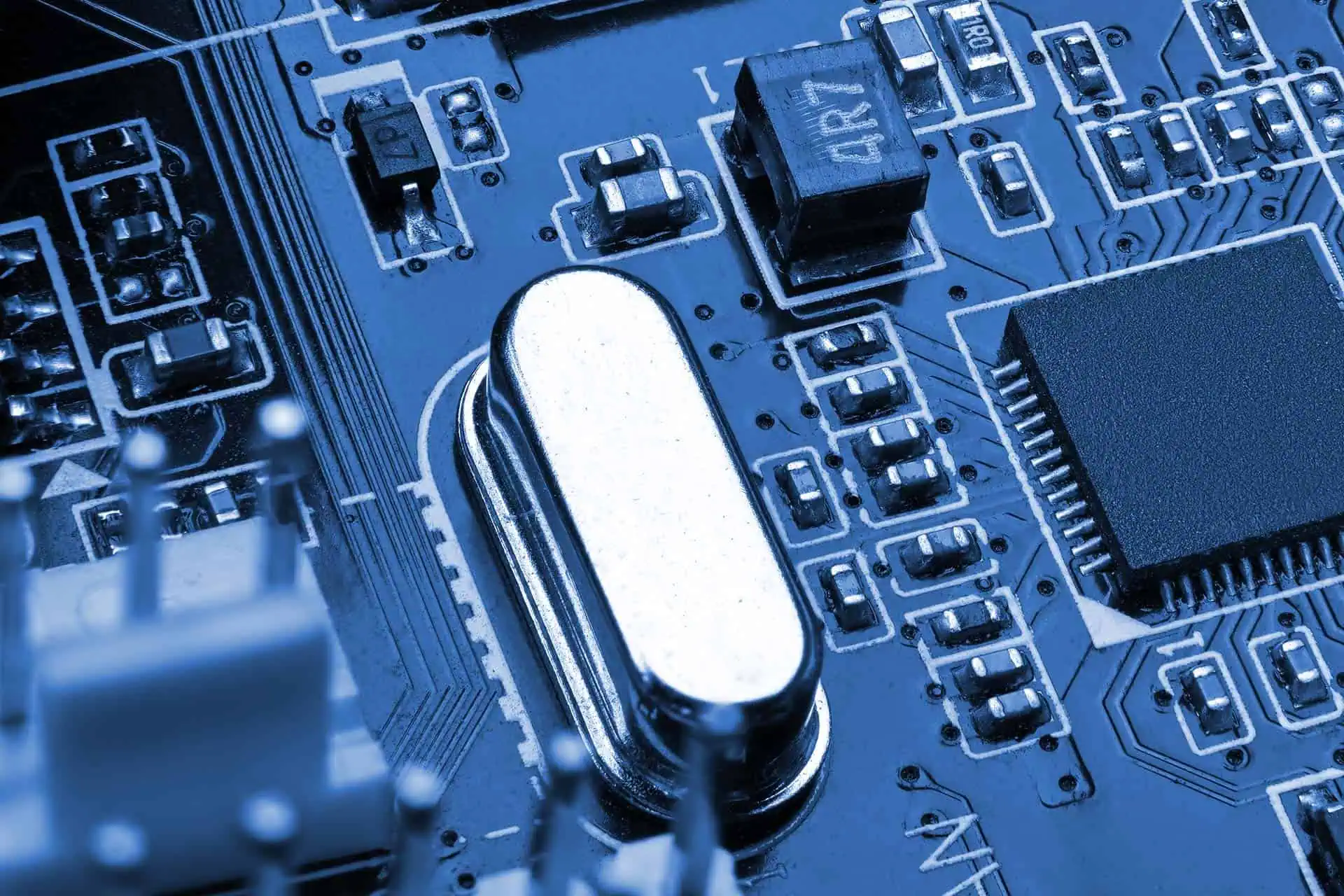

Printed Circuit Boards (PCBs)

Single- & multilayer, HDI, FR-4, rigid-flex, and aluminum PCBs – precisely manufactured and of the highest quality.

Crystals & Oscillators

Reliable timing components: precision crystals and oscillators – frequency-stable, compact, and long-term reliable.

Memory Components

High-performance memory solutions: asynchronous SRAMs, serial PSRAMs, and low-power memory.

Cooling Solutions

Efficient thermal management with air and liquid cooling, heat pipes, and heat sinks – fully customizable to your needs.