Touch Panels

Intuitive control for modern electronics

Our touch panels enable precise and user-friendly control.

Whether capacitive or resistive, our touch solutions can be seamlessly integrated with display units or used as standalone interfaces.

Your benefits:

- Robust touch technology with high accuracy

- Capacitive and resistive versions – including multitouch capability

- Customizable to housing, application environment, and user interface

Our touch panels are resistant to environmental influences, offer long service life, and are suitable for use in harsh industrial settings as well as hygiene-sensitive areas.

Custom touch solutions from a single source

Tailored. Versatile. Proven. We support our customers in the development and production of touch panels using various technologies and, if desired, deliver fully assembled solutions – including LCD and housing.

Available touch panel technologies

Resistive touch panels

(4-wire / 5-wire / 8-wire technologies)Capacitive touch panels

(Multitouch – up to 10 fingers)SAW-Touch panels

(Surface Acoustic Wave)Optical touch panels

(Infrared, CCD sensor, or in-cell technology)Electromagnetic digitizer tablet

Hybrid touch panels

Capacitive touch panel specifications

The demand for projected capacitive (PCAP) touch panels – commonly used in smartphones and tablets – has increased significantly in recent years. We are continuously developing solutions to meet these evolving requirements.

Structure and Key features:

Max. screen size:

50 inches (150 cm)

Aspect ratio:

4:3, 16:9, 16:10 or custom formats

Signal activation:

Finger or rubber stylus

Accuracy:

Better than 2.5 mm

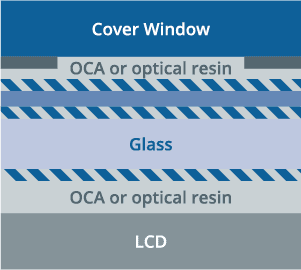

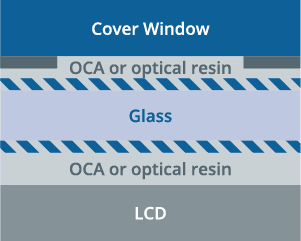

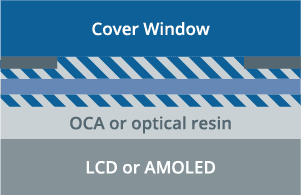

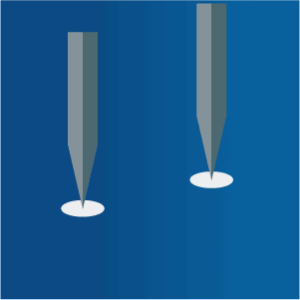

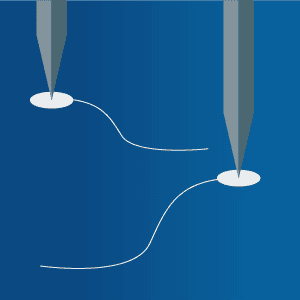

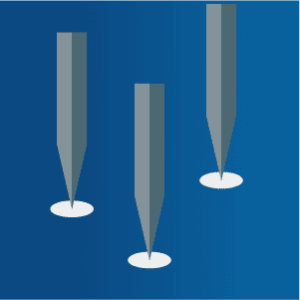

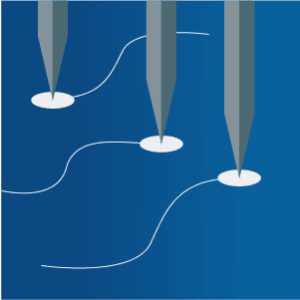

Glass or film substrate touch panel structures with different combinations of glass and film layers (Glass = G; Film = F):

– GG structure (e.g. iPhone – transparency: 90 ±2%)

– GGG structure (vandalism-resistant)

– GF structure

– GFG structure (for outdoor use)

– GFF structure (used by various mobile phone manufacturers)

– GFFF structure

Glass coatings:

Anti-glare coating, anti-reflective coating

LCD resolutions:

– Full HD: 1920 x 1080

– 2K: 2048 x 1080

– 4K / UHD: 4096 x 2160

Housing frame:

Available with or without frame

Temperature ranges:

– Storage temperature: –30 °C to +80 °C

(min. 10% to max. 90% RH)

– Operating temperature: –30 °C to +70 °C

(min. 20% to max. 90% RH)

GG (DITO)

GG (SITO)

G2

G1

GG (DITO)

GG (SITO)

G2

G1

A control board with maximum performance.

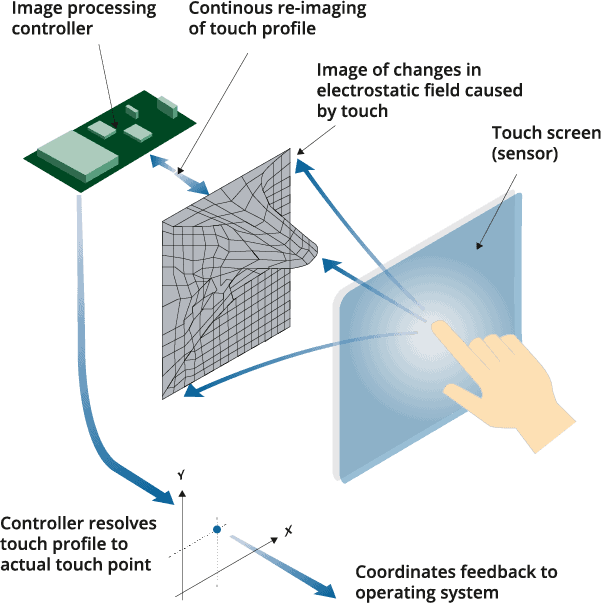

Touch controller functionality

- 10+ point touch detection and tracking (on X and Y axis)

- Palm recognition

- Touch detection latency: 10 ms

- Maximum position update rate : 5 ms

- Maximum response time: 20 ms

Detection and Drive characteristics

High resistance tolerance

High sensitivity: < 0.1 pF (picofarads)

Immunity to LCD noise

Resistance to RF and power line interference

Multi-Touch technologies

Single Touch:

– Resistive Analogue Type

– Surface Capacitive

– Surface Acoustic Wave (SAW)

– Magnetic / Digitizing

Multitouch (2 points only):

– Resistive Multitouch (Win7)

– Projected Capacitive

– SAW – ELO intelliTouch (Win7)

– Magnetic / Digitizing

Gestures:

– Resistive 4 W / 5 W

– Projected Capacitive

Multitouch (more than 2):

– Resistive Multi-Touch

– Projected Capacitive

– CCD

– Hybrid: N-trig

Send us your non-binding

product inquiry.

FAQs

What types of touch panels are available?

The two most common technologies are:

- Capacitive Touch Panels (PCAP):

Multitouch-capable, highly responsive, and transparent – ideal for smartphones, industrial displays, and medical devices. - Resistive Touch Panels:

Pressure-sensitive and operable with gloves or styluses – ideal for industrial environments or hygiene-critical applications.

What is the difference between capacitive and resistive touch technology?

Capacitive: Responds to touch from conductive objects such as fingers. Supports multitouch, but is not ideal for use with gloves.

Resistive: Responds to pressure – whether from a finger, stylus, or glove – and continues to function reliably in wet or dirty environments.

Are your touch panels multitouch-capable?

Yes, especially capacitive panels support two or more simultaneous touch points, enabling gesture control such as zooming and swiping.

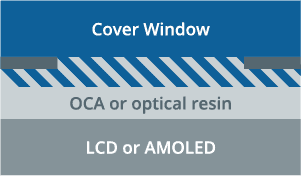

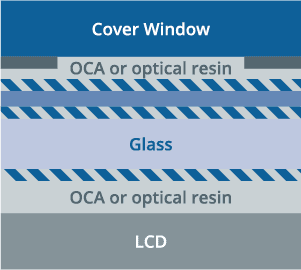

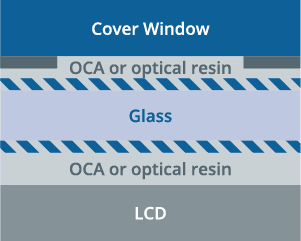

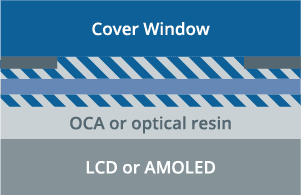

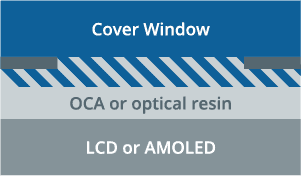

Can touch panels be optically bonded?

Yes. With optical bonding, the gap between the display and the touch sensor is filled with a clear adhesive or resin, offering:

✔ Improved sunlight readability

✔ Reduced reflections

✔ Increased stability & protection against moisture

Are your touch panels suitable for harsh industrial environments?

Yes. We offer rugged touch solutions with:

- IP65 or IP67 protection

- Chemically and scratch-resistant surfaces

- Extended temperature range (–30 °C to +85 °C)

Can touch panels be integrated into custom housings?

Absolutely – our panels are available in various sizes, shapes, and mounting options to fit seamlessly into your enclosure design.

Are your touch panels operable with gloves?

✔ Resistive touch panels are always glove-compatible.

✔ Capacitive panels can be calibrated for glove or stylus operation upon request.

Five good reasons to choose touch panels from etronics

Engineering Support

We support you throughout development and the entire product lifecycle with our engineering expertise and years of experience.

Total Solution

We provide fully integrated, customized solutions combining display, touch panel or films, silicone rubber keypads, front bezels, or complete housings.

Quality is our top priority

We follow established quality standards, apply strict partner selection and testing procedures, and can also carry out validations upon request.

Practice makes perfect

Our consulting services are based on 30 years of experience in designing and manufacturing displays, touchscreens, and enclosures.

Small series? No problem.

With etronics, custom low-volume production is also feasible. Reverse engineering is available if needed.

A smooth process from start to finish: Professional project execution

1. Your inquiry

2. Feasibility check & Solution development

3. Customized quotation

4. Project kickoff & Order placement

5. Prototyping & Sample production

6. Sample approval & Optimization

7. Series production & Quality assurance

8. Delivery & Logistics solutions

Explore more categories

Membrane keypads

Durable, hygienic, and fully customizable – highly resistant, easy to clean, and designed to meet your specific needs.

Resistors by MIBA

MIBA high-performance and precision resistors: non-inductive, compact, and reliable.

Pogo-Pins

Compact, durable, and versatile – premium pogo pins ensuring reliable electrical connectivity in devices and test systems.

Displays

Premium TFT, OLED, and LCD displays – fully customizable, offering excellent contrast and energy efficiency.

Silicone Keypads

Durable and tactile input solutions – fully customizable silicone keypads with excellent chemical resistance.

Custom Cable Assemblies

Individually manufactured to exact specifications and industry standards – safe, precise, and perfectly fitting.

Printed Circuit Boards (PCBs)

Single- & multilayer, HDI, FR-4, rigid-flex, and aluminum PCBs – precisely manufactured and of the highest quality.

Crystals & Oscillators

Reliable timing components: precision crystals and oscillators – frequency-stable, compact, and long-term reliable.

Memory Components

High-performance memory solutions: asynchronous SRAMs, serial PSRAMs, and low-power memory.

Cooling Solutions

Efficient thermal management with air and liquid cooling, heat pipes, and heat sinks – fully customizable to your needs.