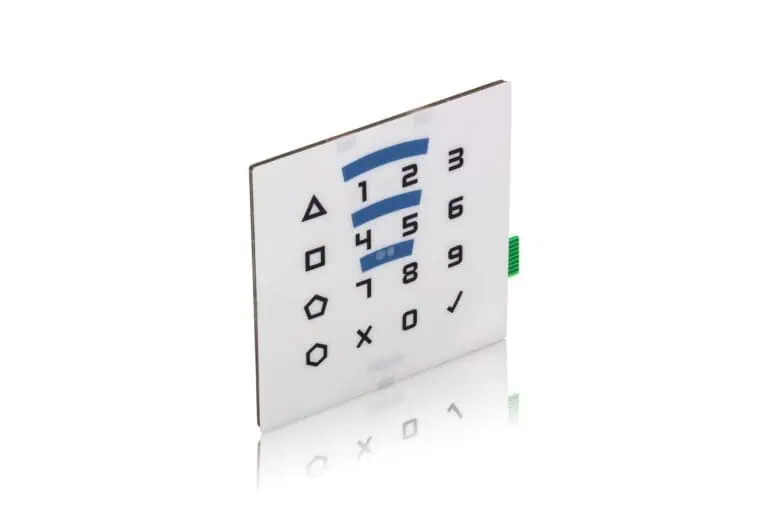

Membrane keypads

Robust control for any application

Our membrane keypads are the perfect solution for demanding user interfaces.

They are waterproof, durable, and resistant to dirt and chemicals – making them ideal for industrial and medical applications. With customizable print designs, optional backlighting, and tactile feedback, they ensure a unique and reliable user experience.

Your benefits:

- Robust surface, resistant to dirt and moisture

- Custom design and printing

- Tactile feedback for precise operation

Membrane Keypads and Graphic Overlays

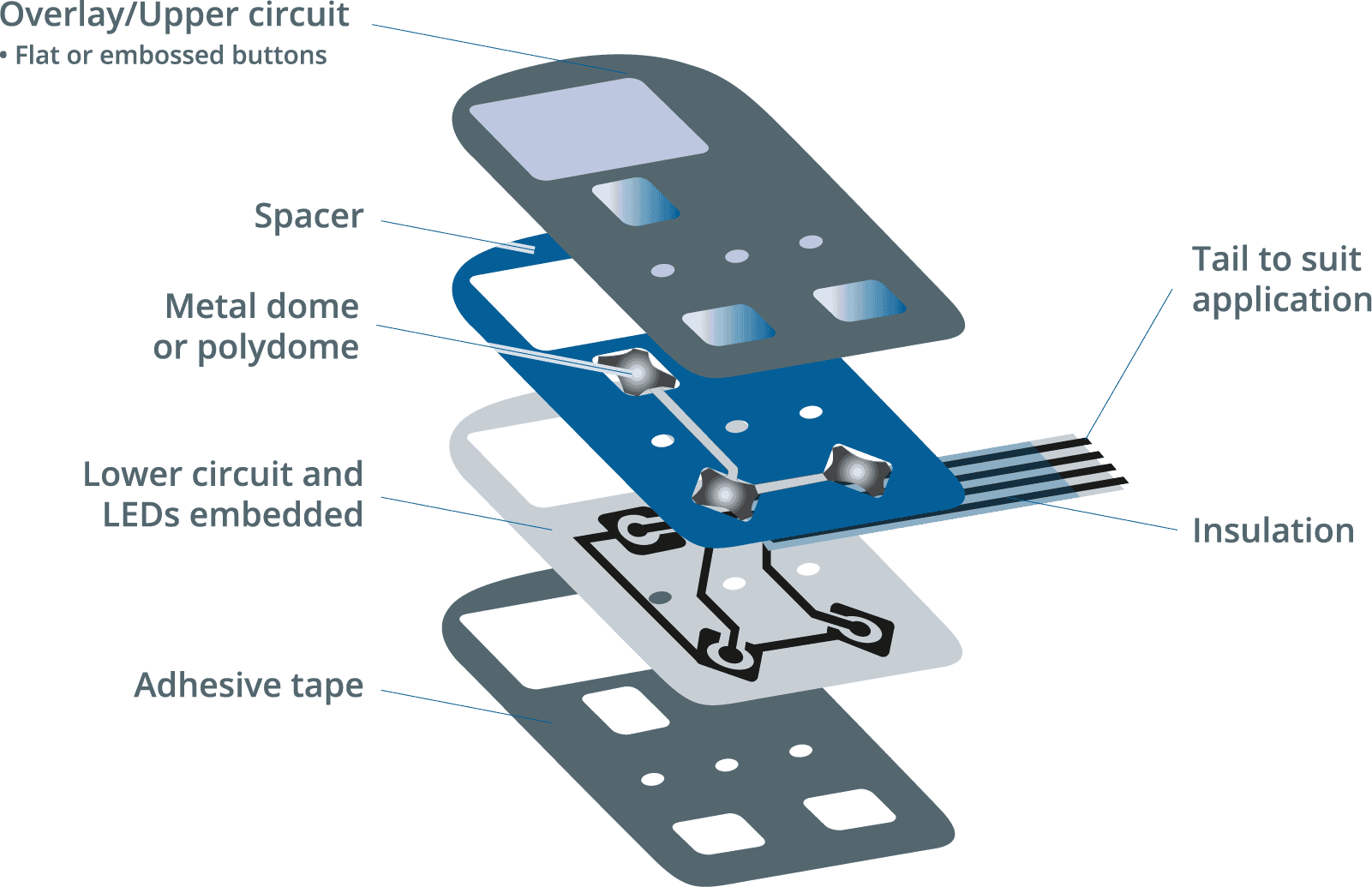

Membrane keypads are robust and modern flat input systems, ideally suited for environments requiring chemical and thermal resistance as well as protection against dust and splashing water. Mounting is typically done using a self-adhesive backing. When delivered on a rigid carrier, mounting may also be achieved by screwing or clamping.

Turnkey Solutions

We take on the role of a project manager with strong engineering expertise, ensuring a seamless transition from design and development to production. Throughout the entire development and manufacturing process, we focus on the quality and cost-efficiency of your final product.

Upon request, we also integrate your membrane keypad …

… with a suitable housing

… with mechanical components such as carrier plates, protective covers, or enclosures

… with electronic components like PCBs, connection cables, or displays

… into a fully assembled unit

Wider range of materials

Choosing the right material for the user interface is crucial to ensuring durability, functionality, and design compatibility. We offer a broad selection of materials, including:

- Polyester (matte or glossy finish)

- Polycarbonate

- PVC

- Aluminium

- Sheet steel

- Stainless steel

- Silicone rubber

Keypads in all sizes, colors & shapes

When it comes to size, shape, and color, membrane keypad design knows virtually no limits. Thanks to a wide range of manufacturing and printing techniques – including screen printing, digital printing, laser marking, and coating – keypads can be printed in single or multiple colors, embossed, coated, and/or labeled.

Excellent tactile feedback

Precise Tactile Response for Reliable Operation

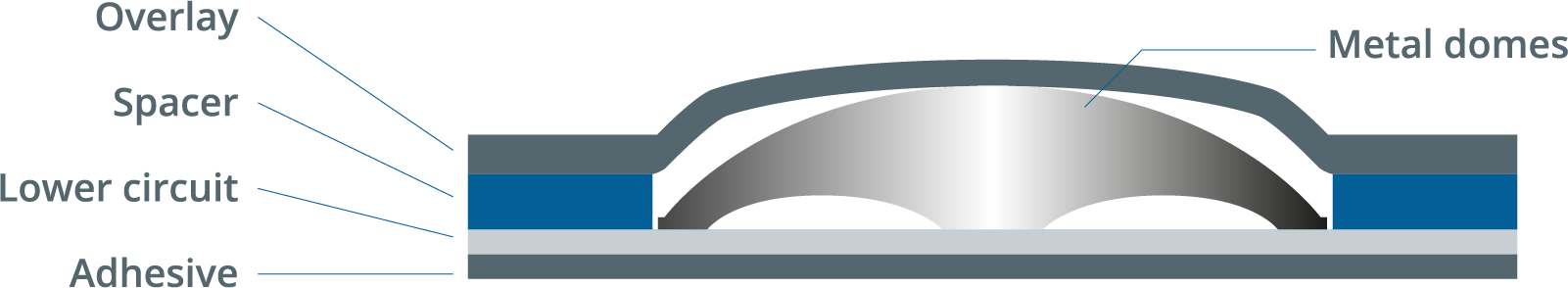

The tactile feel of a keypad is shaped by its surface structure, key travel, and the actuation and return forces. Membrane keypads typically use metal snap domes or polydomes to ensure crisp, reliable switching performance.

Long-lasting performance by design

To ensure lasting protection, your keypad is not treated as a standalone component, but as an integral part of the overall machine. Special attention is given to external influences such as electromagnetic fields, vibrations and shocks, temperature fluctuations, dust, and dirt.

We offer a wide selection of materials and surface coatings that protect the keypad not only from abrasion but also from UV exposure, dirt, and aggressive substances such as nitrite thinners and similar chemicals.

Quality you can rely on

At every stage of production, we adhere strictly to quality standards and legal requirements – from incoming goods inspection to comprehensive final testing (including 100% electrical testing). Our keypads are built to last, with a service life of well over 1 million actuation cycles.

Medical and Industrial development projects

Medical and Industrial development projects

Medical products and also applications in areas such as food production are subject to strict regulations regarding safety and hygiene. That’s why our partners not only hold essential certifications such as ISO 9001 and ISO 13485 (for medical devices), but also offer specialized solutions such as antibacterial coatings that protect the surface from germs. We provide expert support in:

…Selecting the right materials

…Defining tactile and visual characteristics

…Determining actuation force

…Replacing existing input solutions

…Enhancing surface protection and extending durability

…Managing electronic interfaces and system requirements

…Implementing design measures to optimize the overall system

Our many years of experience are reflected in the quality and longevity of the final product.

Send us your non-binding

product inquiry.

FAQs

What are the advantages of membrane keypads?

They are flat, durable, easy to clean, and exceptionally long-lasting – making them ideal for medical devices and industrial control systems.

Can membrane keypads be equipped with backlighting?

Yes, membrane keypads can be backlit using LED or electroluminescent (EL) technology to provide optimal visibility – ensuring optimal visibility.

Can membrane keypads be customized in terms of layout and design?

Absolutely. Key layouts, icons, company logos, and color schemes can all be tailored to your individual needs.

Can ESD or EMC shielding be implemented?

Yes, we can incorporate special layers to provide electromagnetic compatibility (EMC) shielding and electrostatic discharge (ESD) protection.

Five good reasons to choose membrane keypads from etronics

Engineering Support

We support you throughout development and the entire product lifecycle with our engineering expertise and years of experience.

Total Solution

You can either source the membrane keypad as a standalone component or let us integrate it with PCBs, housings, and cable assemblies.

Quality is our top priority

We not only adhere to established quality standards and apply strict selection and testing procedures for our partners, but we can also carry out product validations upon request.

Practice makes perfect

With over 30 years of experience in the development and production of membrane keypads, we know what matters.

Small series? No problem.

We can also realize small and very small production runs of custom keypad solutions – tailored to your needs.

A smooth process from start to finish: Professional project execution

1. Your inquiry

2. Feasibility check & Solution development

3. Customized quotation

4. Project kickoff & Order placement

5. Prototyping & Sample production

6. Sample approval & Optimization

7. Series production & Quality assurance

8. Delivery & Logistics solutions

Explore more categories

Resistors by MIBA

MIBA high-performance and precision resistors: non-inductive, compact, and reliable.

Pogo-Pins

Compact, durable, and versatile – premium pogo pins ensuring reliable electrical connectivity in devices and test systems.

Displays

Premium TFT, OLED, and LCD displays – fully customizable, offering excellent contrast and energy efficiency.

Touch Panels

Capacitive and resistive touch panels – robust, highly accurate, multitouch-enabled, and easily integrated into your device design.

Silicone Keypads

Durable and tactile input solutions – fully customizable silicone keypads with excellent chemical resistance.

Custom Cable Assemblies

Individually manufactured to exact specifications and industry standards – safe, precise, and perfectly fitting.

Printed Circuit Boards (PCBs)

Single- & multilayer, HDI, FR-4, rigid-flex, and aluminum PCBs – precisely manufactured and of the highest quality.

Crystals & Oscillators

Reliable timing components: precision crystals and oscillators – frequency-stable, compact, and long-term reliable.

Memory Components

High-performance memory solutions: asynchronous SRAMs, serial PSRAMs, and low-power memory.

Cooling Solutions

Efficient thermal management with air and liquid cooling, heat pipes, and heat sinks – fully customizable to your needs.