Cooling Solutions

Helping your semiconductors keep a cool head.

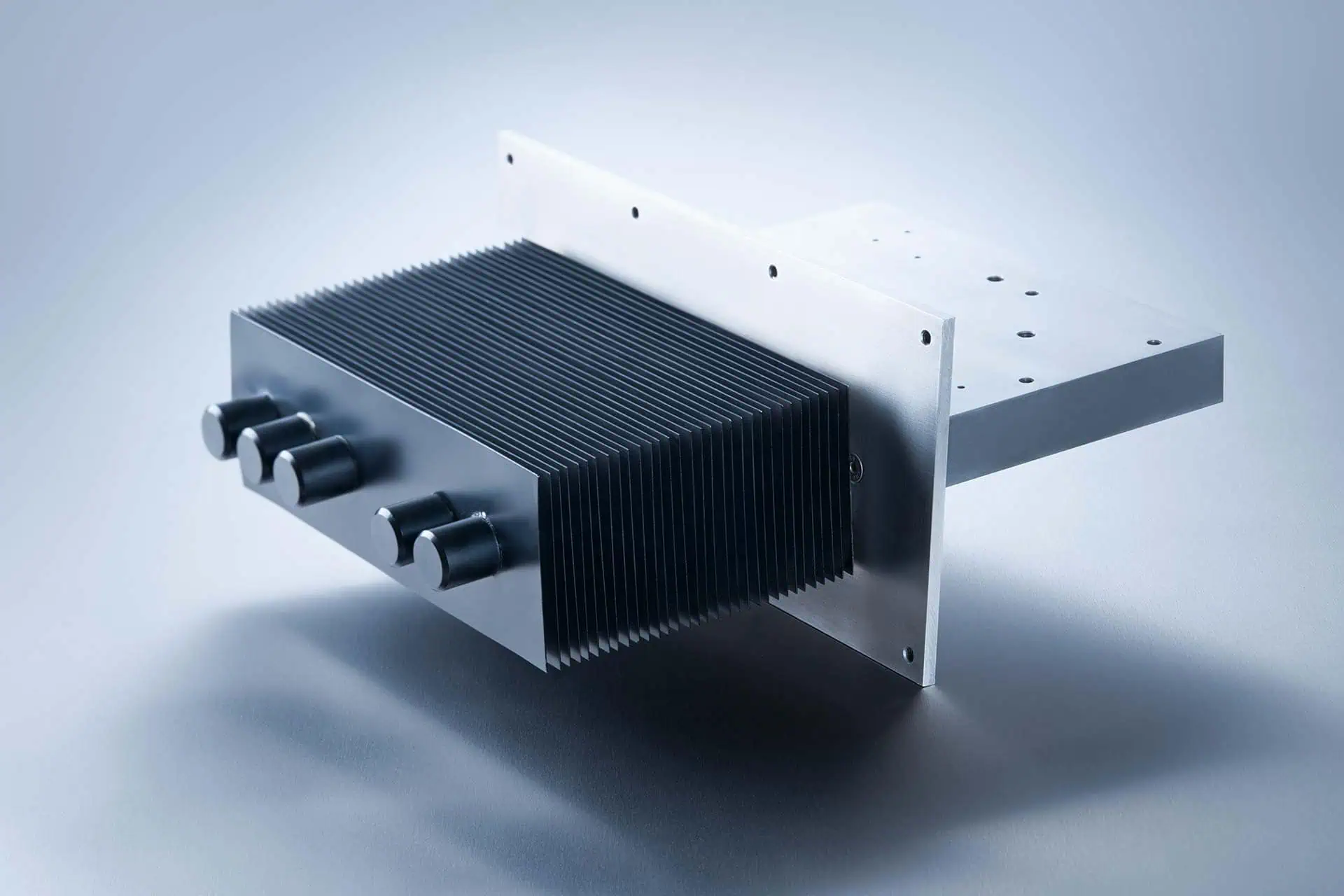

Cooling solutions – efficient heat dissipation for maximum performance

Our cooling solutions ensure optimal temperature control and protect your electronic components from overheating. Whether heat sinks or liquid cooling – we deliver efficient thermal management solutions for every application.

Your benefits:

- Maximum service life and performance of your electronics

- Custom-tailored solutions for various applications

- Energy-efficient cooling technologies

One-Stop thermal management

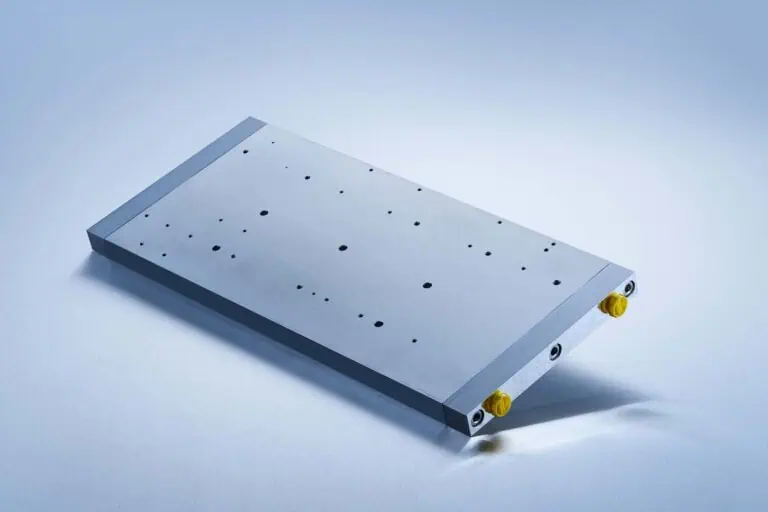

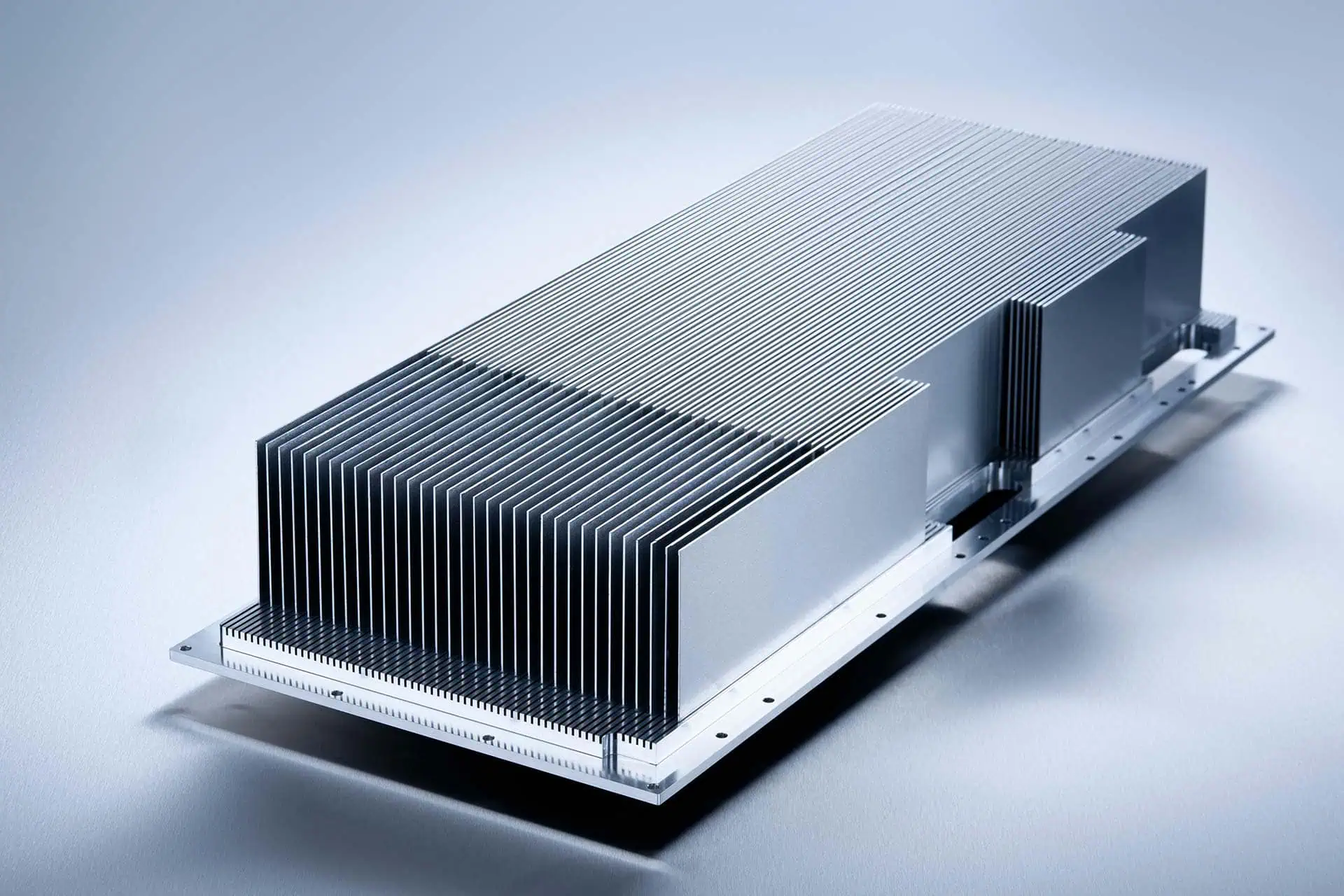

We design, develop, and manufacture custom cooling solutions tailored to your requirements. Depending on the application, we offer air-cooled heat sinks, water-cooled heat sinks, or vacuum-brazed coolers.

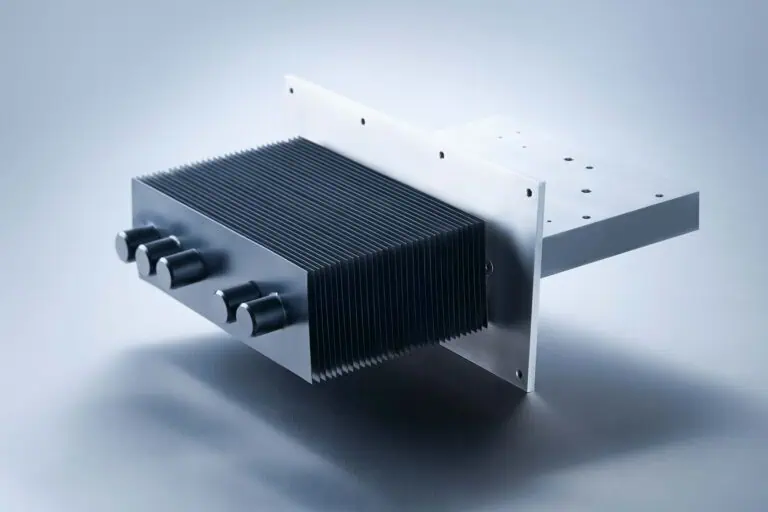

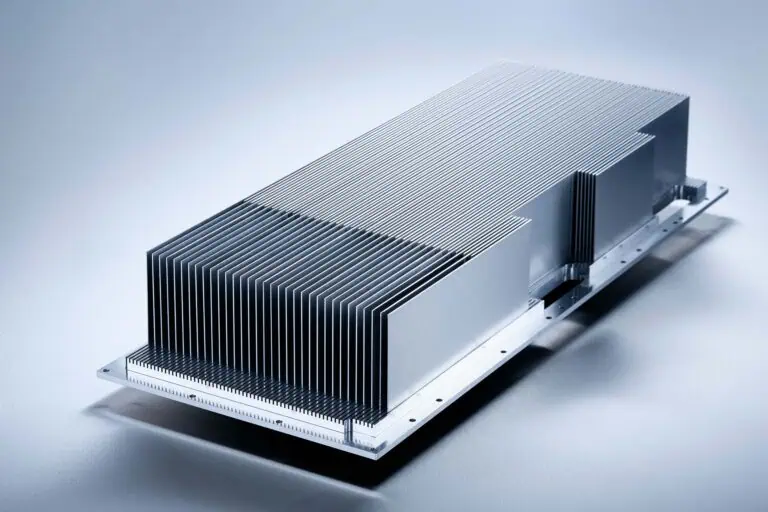

Custom air cooling – optimized for your industry

Tailored cooling solutions for your product

Our experienced thermal design engineers work closely with you to develop the ideal air-cooling system – precisely matched to your industry and application requirements.

We offer:

- Customized profile solutions

- Application-specific bonded-fin heat sinks with various joining methods and geometries

- Individually configured assemblies

Our goal is to provide the exact cooling solution that maximizes the efficiency and success of your product and project.

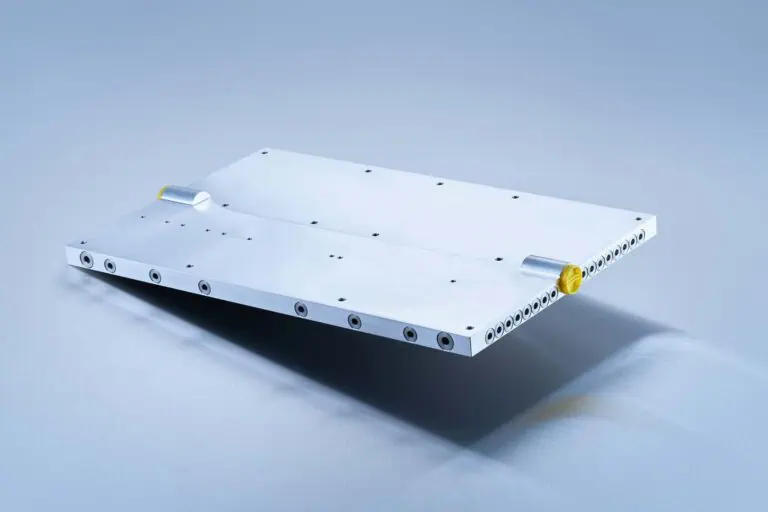

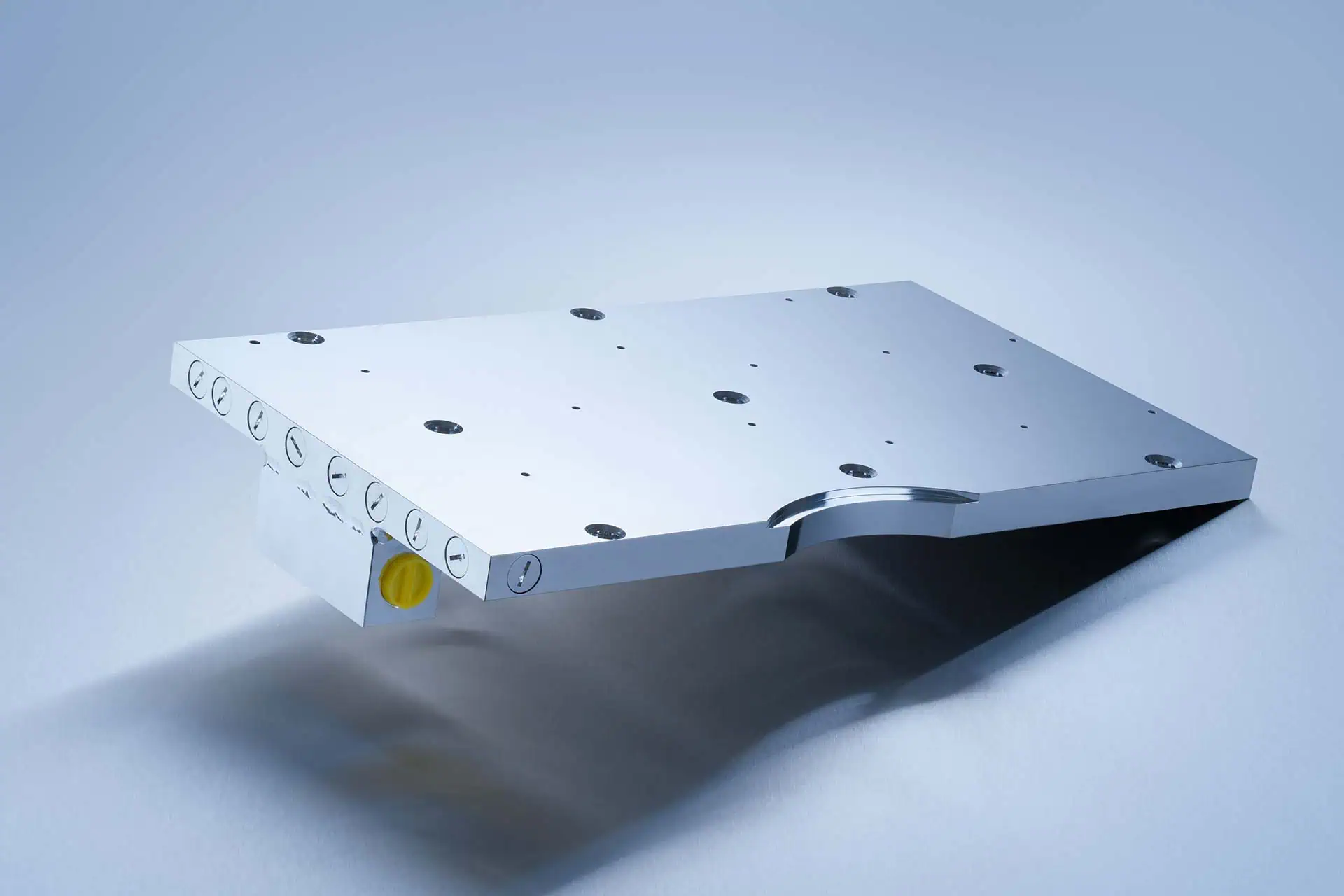

Industrial water coolers

Innovative cooling technologies for the highest demands

Miba Cooling continuously develops new solutions to ensure that even the most advanced power semiconductors can operate reliably and efficiently under extreme conditions. Industrial water coolers play a key role in the performance and longevity of electronic components.

Key functions at a glance:

- Efficient dissipation of heat from specific power semiconductors

- Reduction of power loss generated during operation

- Protection of power electronic systems from overheating and failure

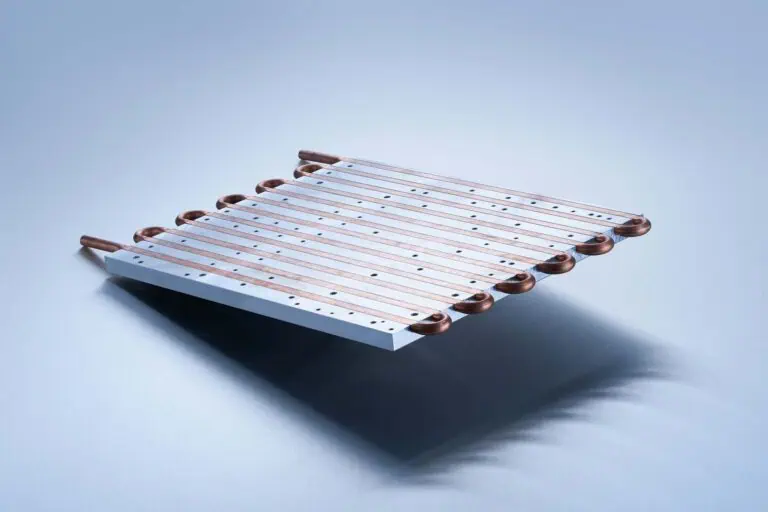

Miba Heatpipe

Send us your non-binding

product inquiry.

FAQs

Which cooling solutions do you offer?

We offer air coolers, water coolers, heat pipes, as well as custom-made heatsinks and thermal assemblies.

How is the right cooling solution selected?

We provide expert advice based on power dissipation, ambient temperature, available installation space, and airflow – including thermal simulation.

Are passive cooling systems also possible?

Yes, passively cooled heat sinks without fans are particularly quiet and maintenance-free.

Are custom heatsink geometries possible?

Yes, almost any shape is feasible using CNC machining, extrusion, milling, or 3D printing – including integration with heat pipes.

Which industries require specialized cooling solutions?

Typical applications include power electronics, industrial systems, e-mobility, medical technology, and renewable energy.

Five good reasons to choose cooling solutions from etronics

We solve almost any thermal challenge

Whether it's flow accelerators, vacuum-brazed heat sinks or other innovations – for semiconductors with high power densities, we ensure optimal heat distribution and dissipation.

Flexible semiconductor arrangement

Thanks to the special internal structure of our vacuum-brazed heat sinks, we can design the water channels flexibly to provide optimal cooling directly beneath the semiconductors.

Customized heat sink design

Our channel design is also highly adaptable. It ensures uniform water flow, minimal pressure drop and maximum heat dissipation efficiency.

Quality Is Our Top Priority

Only what passes our rigorous tests is approved: Extensive testing for tightness, temperature distribution and water flow guarantees the highest level of quality.

Practice makes perfect

Innovation builds on experience: Miba brings over 45 years of expertise in the design and production of heat sink solutions.

A smooth process from start to finish: Professional project execution

1. Your inquiry

2. Feasibility check & Solution development

3. Customized quotation

4. Project kickoff & Order placement

5. Prototyping & Sample production

6. Sample approval & Optimization

7. Series production & Quality assurance

8. Delivery & Logistics solutions

Explore more categories

Membrane keypads

Durable, hygienic, and fully customizable – highly resistant, easy to clean, and designed to meet your specific needs.

Resistors by MIBA

MIBA high-performance and precision resistors: non-inductive, compact, and reliable.

Pogo-Pins

Compact, durable, and versatile – premium pogo pins ensuring reliable electrical connectivity in devices and test systems.

Displays

Premium TFT, OLED, and LCD displays – fully customizable, offering excellent contrast and energy efficiency.

Touch Panels

Capacitive and resistive touch panels – robust, highly accurate, multitouch-enabled, and easily integrated into your device design.

Silicone Keypads

Durable and tactile input solutions – fully customizable silicone keypads with excellent chemical resistance.

Custom Cable Assemblies

Individually manufactured to exact specifications and industry standards – safe, precise, and perfectly fitting.

Printed Circuit Boards (PCBs)

Single- & multilayer, HDI, FR-4, rigid-flex, and aluminum PCBs – precisely manufactured and of the highest quality.

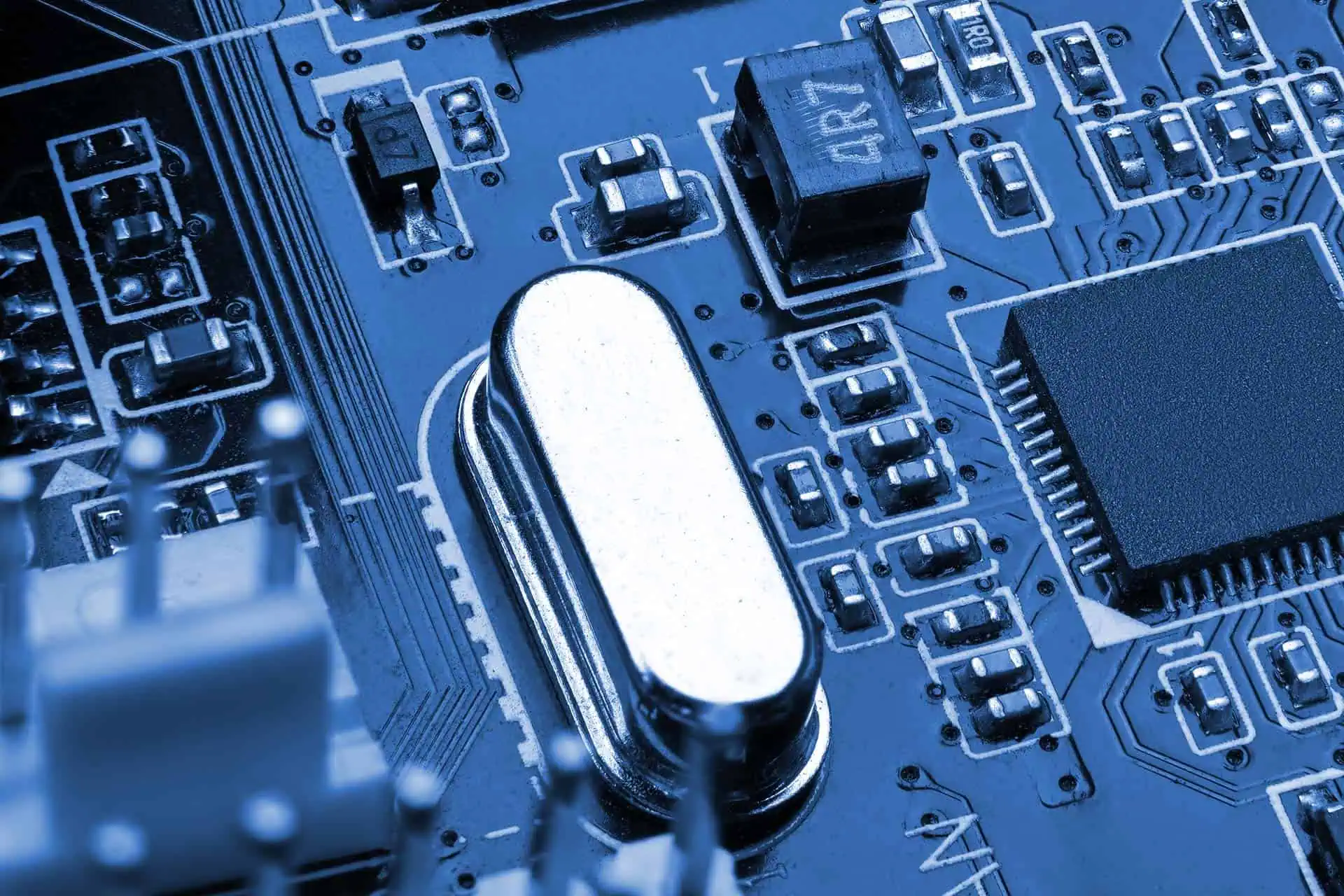

Crystals & Oscillators

Reliable timing components: precision crystals and oscillators – frequency-stable, compact, and long-term reliable.

Memory Components

High-performance memory solutions: asynchronous SRAMs, serial PSRAMs, and low-power memory.