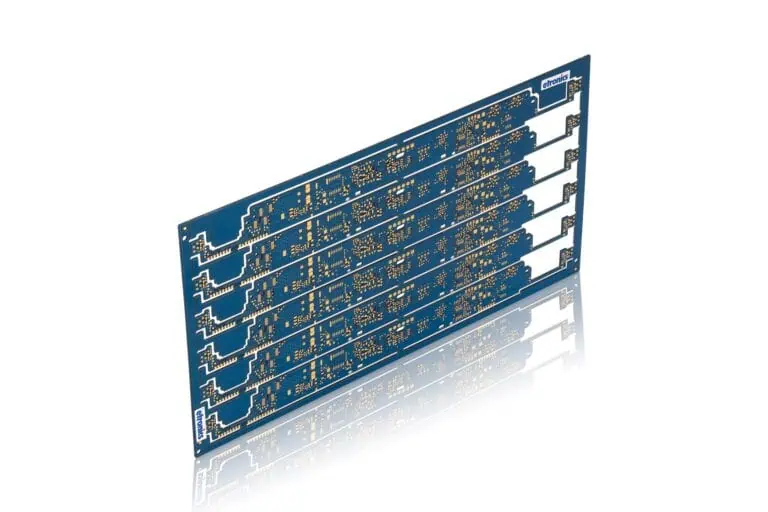

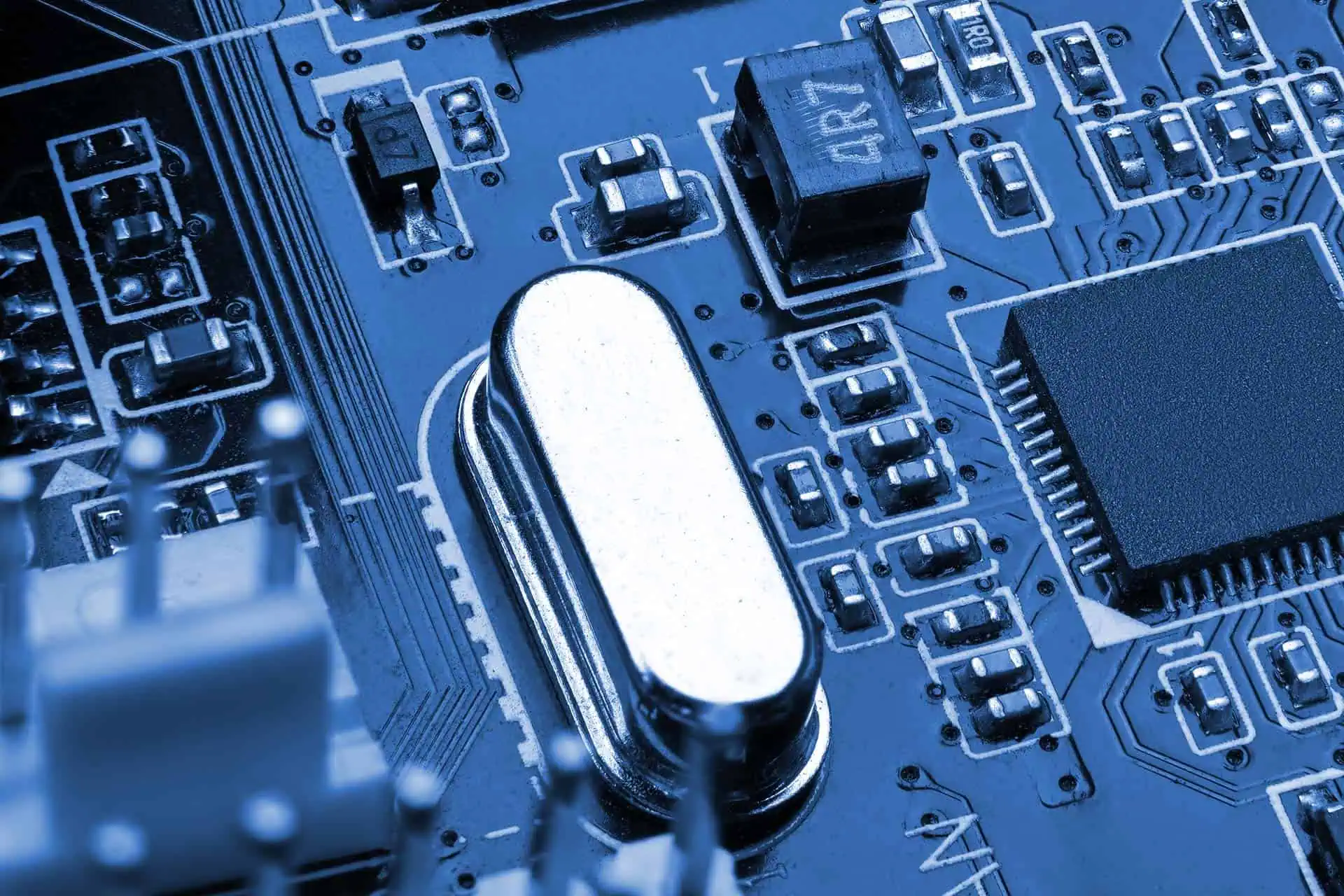

Printed Circuit Boards (PCBs)

Precision for your electronic projects

Our high-quality printed circuit boards offer maximum reliability for your electronic applications.

Manufactured using state-of-the-art production technologies, they ensure stable signal transmission, minimal interference, and long-lasting performance. Choose from single- or multilayer PCBs, flexible or rigid designs – ideal for complex circuits or high-frequency applications. Custom configurations and tailored solutions make your projects even more efficient.

Your benefits:

- Maximum precision and quality

- Custom layouts and modifications

- Ideal for industrial, automotive, medical, and more

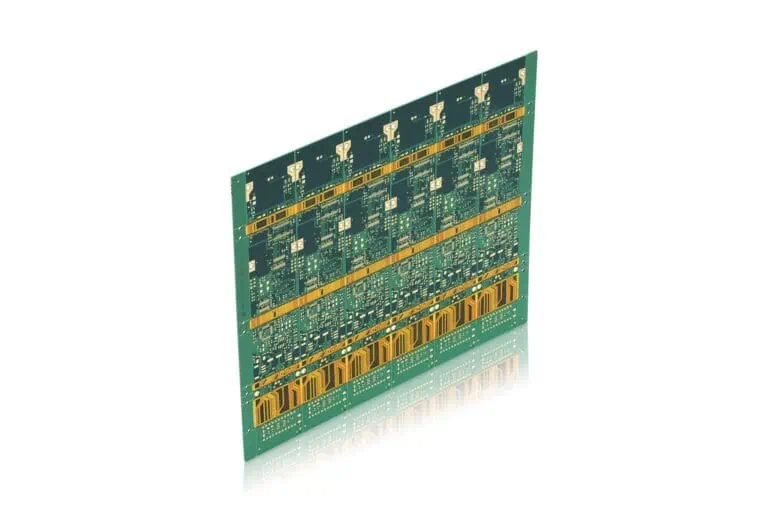

All-in-One PCB Expertise

For us, printed circuit boards are a microcosm of possibilities. Designing and manufacturing them together with our partners is both our passion and our strength. When it comes to size, shape, materials, and surface finishes, there are virtually no limits. We also produce special cores, advanced manufacturing techniques, and complex fine-line structures with ease.

The Ideal Foundation for Every Application

Benefit from true variety. etronics offers a wide range of base materials for printed circuit boards:

- FR-4 (TG 135–200, halogen-free)

- CEM-3 (Composite Epoxy Material)

- Aluminium

- Microwave & RF

- Teflon (Arlon, Roger)

- Ceramic

- Polyimide

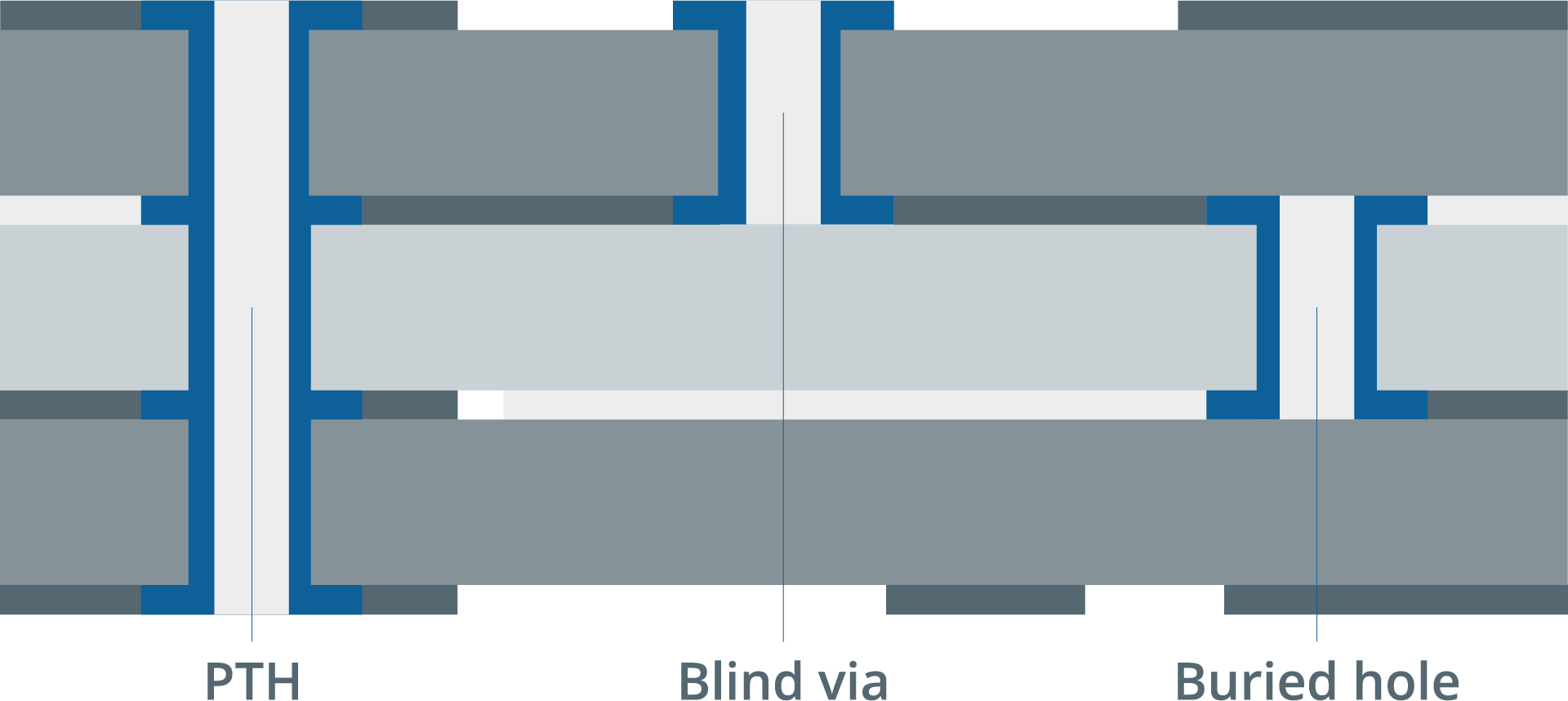

- We also support special technologies and PCB types such as HDI (High Density Interconnect), BVH (Blind Via Holes), and VIP (Via-In-Pad).

Durable Protection by Design

Surface finishes ensure solderability throughout the entire storage period. You can choose from the following methods:

- Nickel/Gold for soldering or adhesive bonding (ENIG / immersion gold)

- Lead-free hot air solder leveling (HASL)

- Gold for wire bonding

- Tin/lead electroplating and reflow

- Electroless silver

- Electroless tin

- Solder mask (available in green, blue, black, red, and white)

- Peelable solder mask

- Kapton tape

- Organic solderability preservative (OSP)

- Carbon ink applied via screen printing

Drilled with Precision

Surface finishes ensure solderability throughout the entire storage period. You can choose from the following methods:

Drilling requires the highest level of precision. We pay close attention to ensuring that…

…solderability is guaranteed

…no glass fibers penetrate the plating

…layer-to-layer misalignment does not exceed 0.102 mm

- Hole position accuracy: ±0.051 mm

- Tolerance (non-plated hole diameter): ±0.025 to ±0.051 mm

- Tolerance (plated hole diameter): ±0.051 mm

- Minimum via size (mechanical drill): 0.102 mm

- Minimum via size (laser drill): 0.076 mm

Blindbohrungen und vergrabene Löcher sind möglich.

Send us your non-binding

product inquiry.

FAQs

What types of printed circuit boards do you offer?

Single-sided, double-sided, multilayer (multilayer PCBs), HDI, rigid-flex, and aluminum PCBs – each tailored to your specific project requirements.

How do single-layer and multilayer PCBs differ?

A single-layer PCB features just one conductive copper layer, making it suitable for simpler circuits. Multilayer PCBs, on the other hand, consist of multiple copper layers laminated together, enabling compact, high-density routing for advanced electronic systems.

Which materials are used in printed circuit boards?

Common materials include FR-4, aluminum, Rogers, and flexible substrates – selected based on thermal, mechanical, and electrical requirements.

Can I provide custom PCB layouts?

Yes, we also manufacture according to individual layouts and support you from prototype development through to series production.

Do you also offer prototype manufacturing?

Yes, we produce both prototypes and series in small or large volumes – including express service upon request.

Five Good Reasons to Choose PCBs from etronics

Quality Is Our Top Priority

We demand the highest quality standards for our products. Quality is at the core of every process step and is verified through comprehensive testing. Compliance with IPC standards and UL approvals is a matter of course for us.

Short development and Production times

We produce prototypes in the shortest possible time – helping you reduce your overall product development cycle.

We Work Only with Professionals

Partnership requires trust. That's why we apply a strict selection process. Our engineers review the PCB design and suggest improvements to enhance manufacturability and reliability.

Practice makes perfect

Our expertise is based on experience. For over 25 years, we’ve been developing and producing PCBs – and we know where to pay special attention.

Excellent Performance at a Fair Price

Thanks to high order volumes, we can negotiate attractive pricing conditions with our partners – and we pass these cost benefits directly on to you.

A smooth process from start to finish: Professional project execution

1. Your inquiry

2. Feasibility check & Solution development

3. Customized quotation

4. Project kickoff & Order placement

5. Prototyping & Sample production

6. Sample approval & Optimization

7. Series production & Quality assurance

8. Delivery & Logistics solutions

Explore more categories

Membrane keypads

Durable, hygienic, and fully customizable – highly resistant, easy to clean, and designed to meet your specific needs.

Resistors by MIBA

MIBA high-performance and precision resistors: non-inductive, compact, and reliable.

Pogo-Pins

Compact, durable, and versatile – premium pogo pins ensuring reliable electrical connectivity in devices and test systems.

Displays

Premium TFT, OLED, and LCD displays – fully customizable, offering excellent contrast and energy efficiency.

Touch Panels

Capacitive and resistive touch panels – robust, highly accurate, multitouch-enabled, and easily integrated into your device design.

Silicone Keypads

Durable and tactile input solutions – fully customizable silicone keypads with excellent chemical resistance.

Custom Cable Assemblies

Individually manufactured to exact specifications and industry standards – safe, precise, and perfectly fitting.

Crystals & Oscillators

Reliable timing components: precision crystals and oscillators – frequency-stable, compact, and long-term reliable.

Memory Components

High-performance memory solutions: asynchronous SRAMs, serial PSRAMs, and low-power memory.

Cooling Solutions

Efficient thermal management with air and liquid cooling, heat pipes, and heat sinks – fully customizable to your needs.